Format: PDF

Category: Maintenance, operations, and equipment reliability

Length: 1 page

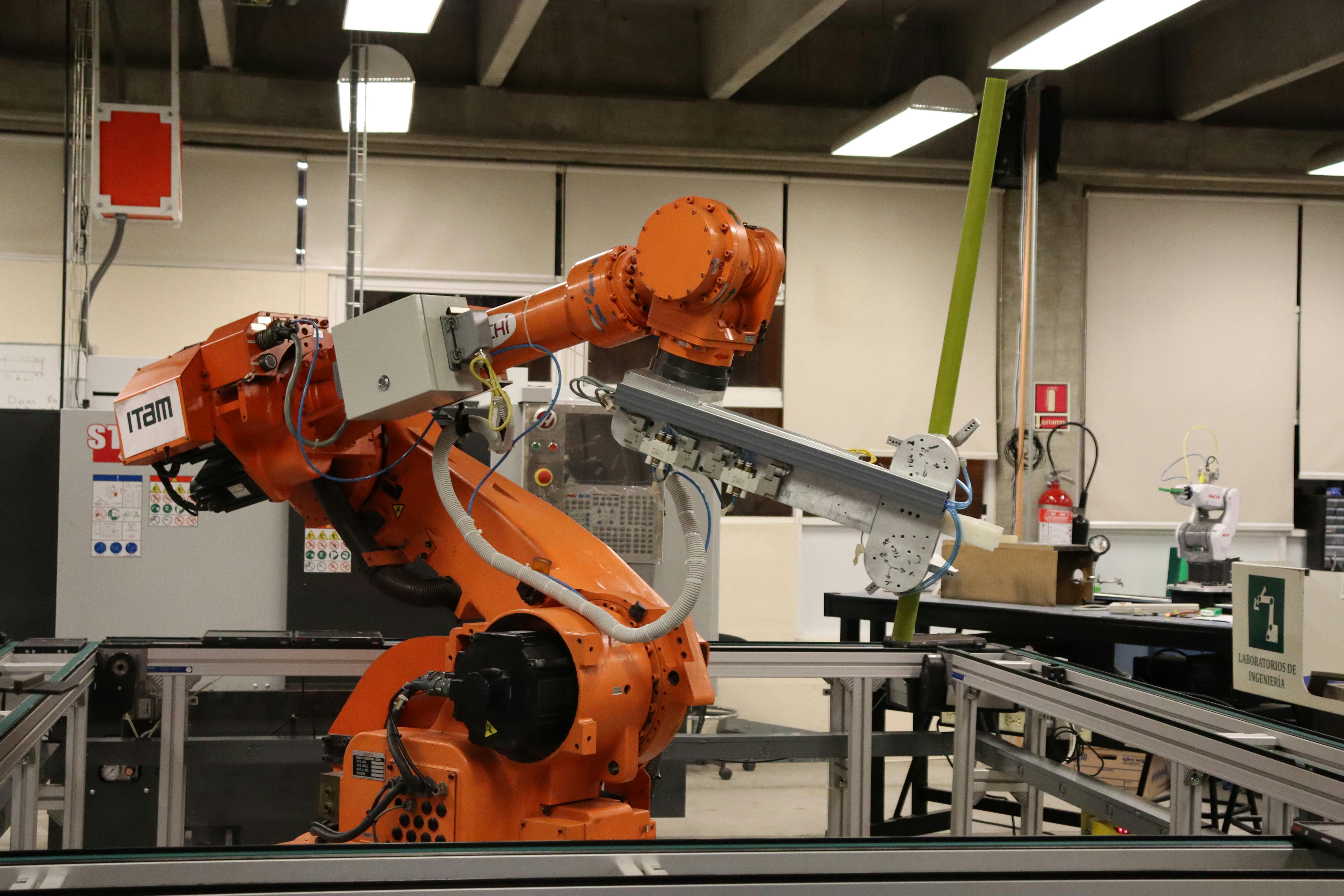

Hidden issues can create big production downtime, discover how to prevent it.

This free, practical checklist for preventive industrial robot maintenance, is designed to help technicians and supervisors catch issues early, maintain precision, and ensure safe operation.

It includes:

Daily, weekly, monthly, quarterly, and annual maintenance tasks

Checks for sensors, actuators, gears, controllers, and electrical connections

Lubrication, cleaning, and calibration guidance for critical components

Safety inspections and emergency stop verification

Use this guide to standardize robot maintenance, prevent unplanned downtime, extend equipment lifespan, and keep your team safe and productive.

What You'll Achieve

Reliable robots that stay precise and productive

Prevent robot downtime

Detect wear, misalignment, and control issues early before they stop production.

Maintain motion accuracy

and repeatabilityKeep axes, joints, gears, and reducers properly

calibrated and aligned.Improve safety around robotic cells

Ensure emergency stops, sensors, and safety systems function as intended.

Extend robot lifespan

Reduce mechanical stress and premature wear through consistent lubrication and inspections.

Standardize maintenance

across teamsApply the same preventive routine daily, weekly, and annually to reduce variability and errors.

Who It's For

Designed for industrial maintenance teams

Maintenance

Perform daily inspections, preventive checks, and corrective actions on robotic systems.

Automation

Monitor sensors, controllers, safety devices, and robot fault indicators.

Mechanical

Inspect gears, reducers, joints, cables, and mechanical wear points.

Operation

Maintain consistent robot performance while supporting safety and reliability.

Get your free maintenance checklist

Stay ahead of failure and keep your robots running smoothly.